As one of the key links in the industrial control industry chain, electric control cabinet system integration plays an important role in the industrial automation and equipment manufacturing industries, and is responsible for providing reliable electrical complete sets of equipment to users in various industries. However, the previous step-by-step production method of electric control cabinets relied heavily on skilled workers, resulting in high costs, low efficiency, and unstable product quality.

The electrical control cabinet industry urgently needs to change the traditional manufacturing management model with increasingly high costs, and the industry is looking forward to the arrival of industrial transformation.

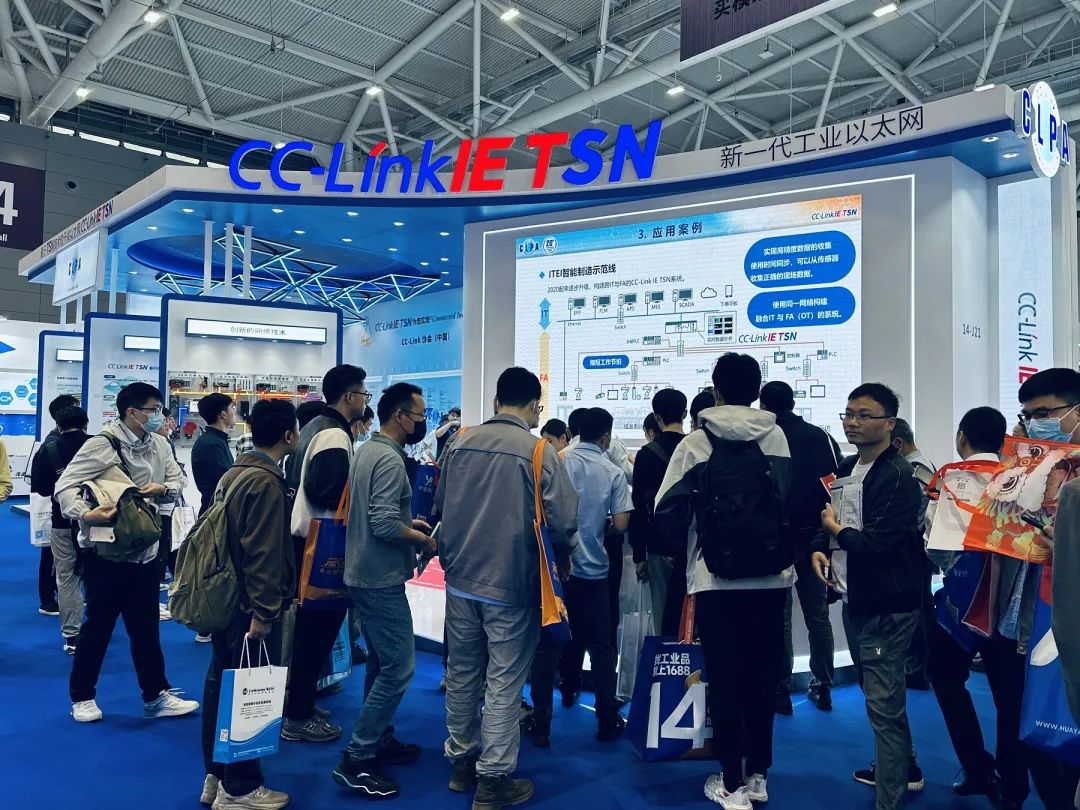

Recently, the “Digital Intelligent Manufacturing·Sparks Spreading Across the Country” SKYCORE Volcano Lake Super Factory was fully put into production and the launch ceremony of the one-stop electric control cabinet intelligent selection “e+” platform was grandly held in Jingxian County, Xuancheng, Anhui. With this, Volcano Lake, based on electrical collaborative design software, connects each link of principle design, process prototype design, smart supply chain, and shared large-scale flexible manufacturing with data, creatively creating a digital ecological full value chain for electric control cabinets. Chain, becoming the industry’s first fully digital industrial Internet platform enterprise for intelligent manufacturing of electric control cabinets.

Committed to leading the development of industrial Internet

Founded in 2020, Volcano Lake is an industrial Internet company that provides customers with professional digital electrical collaborative design software services based on cloud deployment and prefabricated package delivery in the “super factory” model for the industrial manufacturing and electrical automation industries.

“We are a relatively young company, but in fact, most of our founding team members are veterans in the industrial control industry, entrepreneurs with brilliant and successful experiences, and experts who have worked in multinational companies for decades. At the same time, We have also attracted many outstanding young talents from the IT industry. “Volcano Lake co-founder and CEO Tao Hai told the China Industrial Control Network reporter that Volcano Lake’s vision is to help the country’s manufacturing industry upgrade and become a leader in the global industrial Internet. .

Tao Hai believes that in the field of electrical automation control integration in China, there has been little progress in the past few decades, with low standards, poor efficiency, and low degree of standardization. The electric control cabinet and complete set market is facing an industry reshuffle. Therefore, Volcano Lake The founding partners of began exploring a standardized production and manufacturing process many years ago.

“We focus on how to make electrical control cabinets better, more efficient and at a lower cost!” Tao Hai said that Volcano Lake takes professional design as its source and aims to improve efficiency, reduce costs, improve quality and accelerate delivery. By building a collaborative, win-win, digital industrial Internet platform, we empower enterprise users, help them achieve digital and information transformation and upgrading, solve problems such as uncontrollable quality, low production efficiency, and high labor costs, and thus enhance the core competitiveness of enterprises in all aspects. .

In just a few years since its establishment, Volcano Lake has achieved rapid development and completed several rounds of financing. Volcano Lake SKYCORE-EB electrical collaborative design software and SKYCORE-DFM process prototype design software have been launched and iterated, and Yangzhou prefabricated wiring harnesses and Shanghai prefabricated assembly sharing Factories were established one after another, and a Suzhou R&D center was also set up. With the official production of the Anhui Super Factory, Volcano Lake Electric’s prefabricated package delivery service has reached a new level.

Explore new models for sustainable industrial development

Tao Hai pointed out that the traditional production of electric control cabinets mainly follows the order of design – procurement – integration – commissioning and delivery. This traditional and customary production method is doomed to high costs, difficult to control risks and low efficiency. How to reduce costs, control risks, improve quality and ensure delivery has become a pain point for companies. Thus, the one-stop electric control cabinet intelligent selection “e+” platform came into being.

Relying on the “e+” platform, Huoshan Lake can more conveniently provide industry customers with a package of solutions and product services ranging from electrical design, collaborative procurement and supply chain, to prefabricated package delivery, truly demonstrating the innovation created by the smart supply chain in the electric control cabinet industry. Infinite value.

Tao Hai said that the launch of the “e+” platform is an epoch-making move and an innovative achievement of Huoshan Lake in the field of digital ecology. “This is the first time in the electric control cabinet and complete set industry that price quotes can be provided through an Internet platform. It is accurate and can directly form the transaction price.”

“The water of Taohuatan is a thousand feet deep, yet cannot compare to the love that Wang Lun gave me.” Li Bai’s poem “Presented to Wang Lun” has made Taohuatan in Jing County, Anhui Province still well-known to the world thousands of years later. Today, Jingxian County is taking advantage of the momentum and blossoming with industrial beauty. Tao Hai revealed that the Volcano Lake Super Factory located in Jingxian County, Anhui Province is the largest standardized “transparent factory” for electric control cabinets and system integration intelligent manufacturing in China and even in Asia. The total investment of the project is 3 billion yuan. The first phase of the project covers an area of 200 mu, mainly for Focusing on the construction of digital design and intelligent manufacturing base, after production is put into operation, it can achieve an annual output value of 1.5 billion yuan for industrial electrical automation control systems and prefabricated package businesses. The second phase of the project plans to use 300 mu of land, which will be used for the construction of industrial electrical automation complete sets and the “Super Cloud Warehouse” supply chain platform. It is expected that after completion, it will be able to provide more than 10 billion yuan of electrical control system complete sets for the majority of complete set enterprise partners and customers. Serve.

Tao Hai further introduced that the Volcano Lake Anhui Super Factory is equipped with advanced production equipment and manufacturing processes, which can increase the manufacturing efficiency and delivery speed of cabinets and complete sets by more than 5 times. In addition, by directly generating process manufacturing data through front-end digital design and simulation technology, the super factory can efficiently complete the prefabrication of customized openings and tapping of cabinets and mounting plates, and ultimately complete 60-80% of the work in the electrical complete set production process. When the system is delivered to customers, they only need to complete the installation, wiring, possible programming and debugging of key main components and standard components, transforming the step-by-step production method into a parallel workflow, effectively helping customers improve the efficiency of the entire process. Improve product quality, reduce manufacturing costs, truly solve the pain points of manufacturing companies, and provide new models and directions for the sustainable development of the entire industry.

Work together to build an industrial cooperation ecosystem

One travels faster alone; one travels farther in a group. Volcano Lake’s industry partners, including Phoenix Contact, Bokai Machinery, Zhejiang Zhongkong, Siemens, Honeywell, Chery Automobile, Austar Electric, Shanghai Xinhua, etc., attended the celebration. Tao Hai said that the market is changing rapidly and Volcano Lake is actively Build an industrial cooperation ecosystem and unite ecosystem partners to achieve win-win development.

“In the future, if companies want to develop, cooperation is the first priority. This is different from the previous single-handed struggle. We believe that whoever cooperates first will gain the upper hand in the future. Therefore, Volcano Lake is thinking ahead and is also ahead. In front.” Tao Hai said.

On the one hand, for different vertical industry application scenarios, Volcano Lake actively builds an industrial Internet ecosystem. As a leader in the global industrial Internet industry, it provides professional and standardized electrical complete set operation and management models to create a new virtuous cycle. Industrial ecology.

At the same time, for future development, Volcano Lake will also work with more upstream and downstream partners to expand its own business scenarios and provide digital intelligent manufacturing solutions for electric control cabinet system integration.

In addition, Volcano Lake also signed chassis and cabinet, prefabricated package strategic agreements with important industry partners such as Anhui Ruixiang Industrial Co., Ltd., Wuxi Woz Intelligent Technology Co., Ltd., and Nanjing Ohm Electrical Technology Co., Ltd. at the celebration event to jointly promote the construction of the industrial ecosystem and deepen Industrial cooperation to achieve strategic win-win results.

Tao Hai said that even the Volcano Lake Super Factory is a model of cooperation, which includes the company’s own strength, the power of capital, and the power of the government. In the future, Volcano Lake will successively invest in such super factories in more regions including the southwest, making more contributions to the development of China’s industry.

Related product recommendations:

SAIA PCD2.M110

ABB PCD231B101 3BHE025541R0101

ABB PCD230A 3BHE022291R0101

SAIA PCD1.M110

ABB SPCD 3D53-AB

SAIA PCD2.C100

ABB PCD230 PC D230 A

ABB PCD232 A101 3BHE022293R0101

ABB PCD235 3BHE032025R0101

ABB 3BHE022293R0101 PCD232

ABB PCD PCD2000 8R38-2031-21-3002

ABB PM858K01

ABB PM864-1A 3BSE018165R1

ABB PM803F 3BDH000530R1

ABB PM864AK01 3BSE018161R1

ABB PM863K02

ABB PM866AK02

ABB PM860

ABB PM856AK01 3BSE066490R1

ABB PM857K01

ABB PM825 3BSC970121R1

ABB PM860K01 3BSE018100R1

ABB PM857K02

ABB PM858K02

ABB PM864 3BSE018151R1

ABB PM861K01

ABB PM876

PPD517A3011 3BHE041576R3011

PPD517 3BHE041576R3011

GFD563A102 3BHE046836R0102

GFD233A101 3BHE022294R0101

GFD563A101 3BHE046836R0101

GFD563A102 3BHE046836R0102

Honeywell FS-QPP-0001

GE IS200SPROH1A

PROSOFT MVI56-DFCMR

ABB PP836A 3BSE042237R2

ABB PP846A 3BSE042238R1

ABB PP885 3BSE069276R1

ABB PP845A

ABB PP825 3BSE042240R1

ABB PP886H 3BSE069297R1

More…