In the manufacturing sector, time-sensitive networking (TSN) has gone from being a developing technology to an essential technology for manufacturing and production systems in just a few years. Its deterministic and microsecond-level interactive characteristics have attracted continuous attention in the field of industrial control with high real-time requirements.

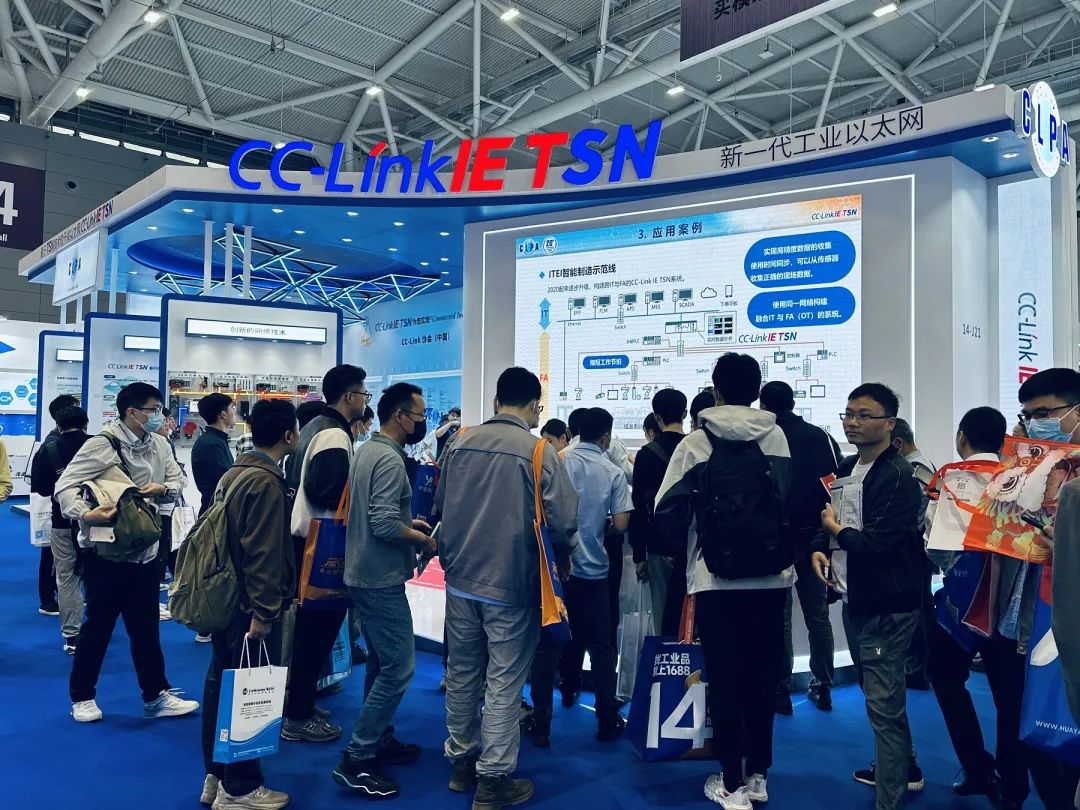

On the other hand, the capabilities of TSN are more evident than ever, thanks to the active role played by future-oriented organizations such as the CC-Link Association, which has strongly supported the development and deployment of TSN in the industrial field from the beginning.

In the view of Zheng Hang, Director of CC-Link Association China Affairs, digital transformation has become an important trend in the development of the world’s manufacturing industry today. To promote the digitalization of the manufacturing industry, it is necessary to collect big data through manufacturing equipment and industrial equipment such as PLC, servos, robots, sensors, etc. used in manufacturing equipment. The role of industrial networks has become increasingly important, and TSN technology can ensure real-time communication between different devices, provide efficient and reliable communication and data exchange capabilities, help improve production efficiency, reduce costs, and lay a solid foundation for accelerating digital transformation and upgrading.

“At the critical moment when CC-Link IE TSN is vigorously promoting the rapid development of intelligent manufacturing, I feel a great responsibility to be responsible for the work of CC-Link Association China,” said Zheng Hang. In September 2022, he officially assumed the position of Director of CC-Link Association China Affairs, comprehensively coordinating the development of CC-Link Association’s various affairs in China.

Zheng Hang, who has a technical background, has extensive industry experience. In his early years, he led the software development of Mitsubishi Electric MELSEC-Q series PLC at Mitsubishi Electric’s headquarters in Japan, and made great contributions to the birth of this classic model. After returning to China, he was responsible for sales in multiple industries and witnessed the development of the domestic industrial network market.

Looking to the future, TSN shows unlimited potential

In the past, factories often needed to build independent multi-layer network architectures on their own to ensure the optimization of efficiency of workstations, production lines, control centers and even the entire enterprise level, and to ensure the smooth operation of various applications and functions. But to build a truly digital factory, we must first break the traditional multi-layer network architecture, effectively solve the problems caused by the integration of IT information technology and OT operation technology, and eliminate the barriers of automated information islands, so as to realize the future outlined by Industry 4.0.

By promoting network convergence while ensuring determinism, an obvious benefit of TSN is that it can simplify the architecture and reduce the number of networks required to support different types of data sharing and communication. In addition to supporting a leaner infrastructure, TSN-enabled convergence also helps improve visibility, transparency, and accessibility. These features can greatly improve operations, increase responsiveness, productivity, and efficiency, and simplify maintenance. More importantly, the convergence of IT and OT makes decisions based on better access to process data more reasonable.

Adhering to the tradition of innovation, the CC-Link Association took the lead in adding TSN capabilities to Industrial Ethernet and launched the CC-Link IE TSN protocol in 2018. CC-Link IE TSN brings together time sensitivity and multi-protocol coexistence to achieve better integration of IT and OT, enabling machine manufacturers and end users to create future-oriented intelligent solutions, improve productivity and efficiency, and ultimately improve competitiveness.

“CC-Link IE TSN network technology is a time-sensitive network technology based on industrial Ethernet. It not only solves the problem of factory IT and OT integration, but also meets the needs of high-response and high-precision real-time control at the field level through the support of gigabit communication speed.” Zheng Hang introduced that TSN technology is becoming a consideration for more and more industrial users to reduce costs and increase efficiency. In the global and Chinese markets, CC-Link IE TSN networks have been widely used in lithium batteries, photovoltaics, automobiles, semiconductors and other industries.

Zheng Hang pointed out that at present in the domestic market, the production systems of these industries are becoming more and more complex, and more axes and more equipment need to be added to cope with them. CC-Link IE TSN is not only compatible with the upper system, but also can be transmitted with multiple lower protocols at the same time, especially in the integration with the current 5G. Therefore, it is very suitable for application scenarios such as remote control, wireless control, and big data parallelism. It conforms to the development trend of future equipment and is a leading solution to help the implementation of Industry 4.0 applications.

Make every effort to build a wider industrial network system

Thanks to CC-Link IE TSN and its leading features, with the support of various automation suppliers, through more and more CC-Link IE TSN compatible products, manufacturing companies are accelerating their journey towards digital transformation.

Zheng Hang revealed that as a global leading industrial network organization with more than 4,000 members, the CC-Link Association fully supports the development of third-party CC-Link IE TSN protocol products. Currently, there are more than 130 compatible products, involving PLC, servo, inverter, touch screen, sensor, remote module, robot, machine vision, etc. “With more diverse development methods, there will be more compatible products in the future to meet customers’ flexible choices.” He said.

At the same time, in order to help member companies launch CC-Link IE TSN compatible products faster, the CC-Link Association is vigorously promoting the construction of CC-Link IE TSN development and evaluation environment, exploring the segmented application market where big data transmission and high response and high precision control coexist, establishing WeChat product platform and promoting CC-Link IE TSN network application solutions, and holding CC-Link IE TSN special technical exchanges to help member companies grasp market demand faster and develop CC-Link IE TSN compatible products.

Not only that, in order to achieve further openness and improve interoperability with other TSN-based industrial networks, the CC-Link Association, together with Avnu Alliance, ODVA, PI International, and OPC Foundation, jointly launched the “TSN Industrial Automation Consistency Cooperation” plan to formulate specifications based on IEC/IEEE 60802 standards to ensure the interoperability and consistency of TSN products. All organizations involved in formulating specifications will use this result as the basis for their respective tests in the future, thereby building a broader industrial network ecosystem.

Zheng Hang said that China’s manufacturing industry has developed rapidly and has accounted for 30% of the world’s total, and digital and intelligent transformation is imperative. The CC-Link Association has been in China for more than 20 years, and has developed together with Made in China. In the future, the CC-Link Association will not only actively promote the CC-Link family network technology to its member companies, but also invest a lot of resources in standard conversion and compatible product promotion; on the other hand, the CC-Link Association will also conduct in-depth research on industry application solutions from the perspective of industry applications to help industry customers achieve the transformation and upgrade of digital factories and intelligent manufacturing.

Related product recommendations:

ABB 3BHE028761R0101

ABB 3BHE025541R0101 PCD231B

ABB PCD230 3BHE022291R0101

ABB PCD230 3BHE022291R0101

ABB SPCD 3D53-AB

ABB PCD230A 3BHE022291R0101

ABB 2711P-RDK7C/C

ABB 3BHE022287R0101 UCD240 A101

Vacon PC00252

ABB PM891K01 3BSE053241R1

ABB PM851AK01 – 3BSE066485R1

ABB PM864AK01 3BSE018161R1

ABB PM861AK02

ABB PM865K01

ABB PM825 3BSE010796R1

ABB PM860K01 3BSE018100R1

ABB PM803F 3BDH000530R1

ABB PM864AK01

ABB PM861AK01 3BSE018157R1

ABB PM864 AK01

ABB PM866AK01

ABB 3BDH000607R1 PM876

ABB PM861AK01 3BSE018157R1

ABB PP881 3BSE092978R1

ABB PP846A 3BSE042238R2

ABB PP865A 3BSE042236R2

PPD103801 3BHE020455R0001

PPD513AOC-100440 3BHE039724R0C3D

PPD517A3011 3BHE041576R3011

ABB PP836A 3BSE042237R2

ABB PP875 3BSE092977R1

ABB PP846 3BSE042238R1

ABB PP836 3BSE042237R1

ABB PP845 3BSE042235R1

ABB 3BSE042236R2

More…

Leave a comment

Your email address will not be published. Required fields are marked *